TX100 T-7 Red Hawk trainer

パイロト養成プログラムを充実させるには、養成に必要な訓練機材、訓練方法とういろんな要素を包括的にとらえることが要求されます。さらに、防衛環境の変化に対応できる、第5世代、6世代の戦闘機のパイロットの養成となると、検討課題は増えるばかりです。今回は、米空軍次世代トレーニングジェットの開発プロジェクトの抱える問題点を契機にして、米空軍のパイロット養成プログラムの抱える課題を勉強し、日本のパイロット養成プログラム改善案の検討の土台作りに寄与できないかなーという願いのもと、関連記事3つをチョイスしました。

空軍の次世代トレーニングジェットの生産は2024年に延期

Design and testing hiccups on the Air Force’s new T-7A Red Hawk training jet, in development at Boeing, have pushed aircraft production into 2024, Air Force Times has learned.

Setbacks have dulled the shine of a program hailed as a major step forward in the adoption of faster, digital-first aircraft design. It also pressures the Air Force to maintain its aging T-38 Talon fleet longer than expected until a replacement is ready.

訂正:この記事の以前のバージョンでは、ボーイング社が2022年第3四半期にT-7Aレッドホーク・プログラムの変更に請求された金額が誤って記載されていました。これは2億8500万ドルに更新されました。

ボーイング社で開発中の空軍の新型ジェット機T-7Aレッドホークの設計とテストの不具合により、航空機の生産が2024年にずれ込んだことが、Air Force Timesの取材で明らかになりました。

この挫折は、より高速でデジタル優先の航空機設計を採用する上で大きな前進となるプログラムの輝きを鈍らせています。また、代替機の準備が整うまで、空軍は老朽化したT-38タロンの機体を予想以上に長く維持することを迫られています。

Pre-production flight testing is slated to start in 2023, and Boeing expects the Air Force will order its first set of operational aircraft in 2024. Inside Defense first reported on potential delays in November.

When the Air Force awarded Boeing a $9.2 billion contract to design and build the next-generation training jet in 2018, the first five operational aircraft were scheduled for delivery in 2023. The service plans to buy 351 Red Hawks, 46 simulators and the associated ground equipment.

生産前の飛行試験は2023年に開始される予定であり、ボーイング社は空軍が2024年に最初の運用機を発注すると予想しています。Inside Defenseが最初に遅延の可能性を報じたのは11月のことでした。

空軍が2018年に次世代訓練用ジェット機の設計と製造を行う92億ドルの契約をボーイングに発注した際、最初の運用機5機は2023年に納入される予定でした。同軍はレッドホーク351機、シミュレーター46機、関連地上機器を購入する予定です。

“We are working with the Air Force to re-baseline the schedule, including identifying opportunities to recover schedule after continued COVID-19 supply chain and workforce disruptions,” Boeing spokesperson Didi VanNierop said in an email.

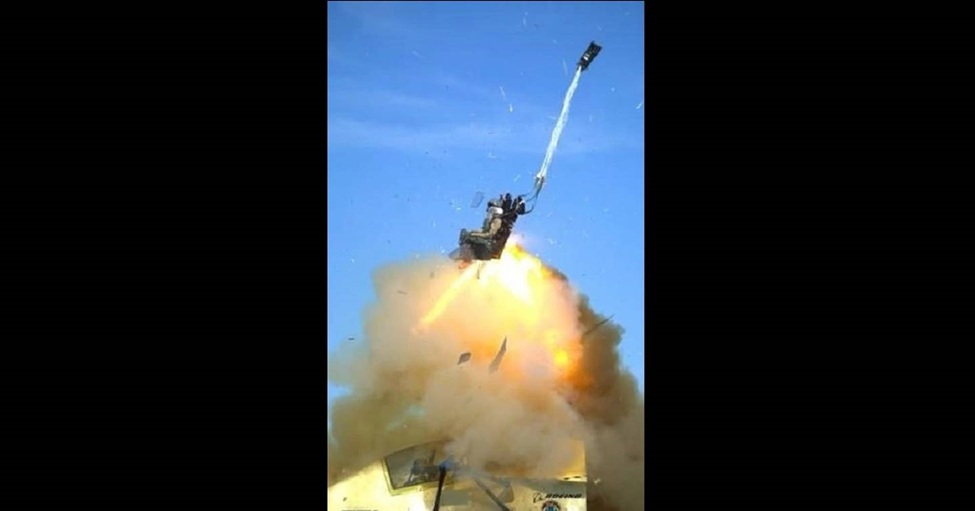

At issue are the emergency egress systems, including ejection seats, and flight control software, Boeing and Air Force officials said.

It’s not your standard ejection system: In 2020, the Air Force mandated that companies must design future aircraft to fit a wider range of recruitable Americans, rather than past standards based on a 1967 survey of male pilots that considered their standing and sitting heights and reach.

That led the Air Force to bar more than 40% of women — particularly women of color — from becoming pilots without a waiver.

“Part of creating a new jet trainer is designing emergency systems with safety and redundancy in mind that enables students to leave the aircraft as safely as possible in the event of an emergency,” VanNierop said. “A new standard of safety has been defined for the T-7A to accommodate the wider range of body types and sizes for future aircrew.”

ボーイング社と空軍の関係者によると、問題は射出座席を含む緊急脱出システムと飛行制御ソフトウエアとあります。

このEjection システムは、標準的な脱出システムでありません。 2020年、空軍は、1967年に行われた男性パイロットの立ち姿や座高、リーチを考慮した調査に基づく過去の基準ではなく、幅広いアメリカ人の採用を可能にするに将来の航空機を設計しなければならないと企業に義務づけていました。

1976年度の調査からの設計規定では、空軍は40%以上の女性、特に有色人種の女性が、その権利放棄をしない限りパイロットになることを禁じていたのです。

「新しいジェット練習機を作ることの一部は、緊急時に生徒ができるだけ安全に機体から離れることができるよう、安全性と冗長性を考慮した緊急システムを設計することです」とヴァンニエロップは述べています。「T-7Aでは、将来の航空機乗務員の幅広い体型やサイズに対応させるため、安全性に関する新たな基準を定めています。

But creating a new jet escape system that works for the vast majority of all potential recruits has proven tricky. The program had conducted 14 qualifying tests on the egress system as of October 2021, when they were paused to address problematic results.

しかし、すべての潜在的な新兵の大多数に対して機能する新しいジェット機脱出システムを作ることは、厄介なことが判明しています。このプログラムでは、2021年10月の時点で14回の脱出システムの資格試験を実施していましたが、問題のある結果に対処するために一時停止されました。

The assessments showed high risk for concussions, unsafe acceleration when a parachute opens, and the possibility that a pilot’s helmet visor could fly off at high speeds, Air Force spokesperson Maj. Alli Stormer said.

“Design improvements are ongoing and escape system testing is planned to resume in [the] first quarter of 2023,” Stormer said.

Previous glitches with the flight control software have been resolved and will head into testing in early 2023 as well. An issue that caused the jet’s wings to rock back and forth was fixed last year.

“We continue to make meaningful progress with the U.S. Air Force on qualification activities while mitigating risk to the schedule,” VanNierop said.

Defense News reported in December 2021 that Boeing expected a formal decision to move out of the engineering and manufacturing development phase of acquisition and into production — known as a “milestone C” decision — in July 2023. The Air Force’s fiscal 2023 budget request, released in April, estimated that will come between October and December 2023.

評価では、脳震盪のリスクが高いこと、パラシュートが開くときに安全でない加速があること、パイロットのヘルメットバイザーが高速で飛ぶ可能性があることが示されたと、空軍広報官のアリ・ストーマー氏は述べています。

“設計の改良は進行中で、脱出システムのテストは(2023年の)第1四半期に再開される予定だ “とストーマーは述べています。

飛行制御ソフトウェアに関する以前の不具合は解決され、同じく2023年初頭のテストに向かう予定です。ジェット機の翼が前後に揺れる問題は、昨年修正されたとほうこくされていす。

「スケジュールに対するリスクを軽減しながら、米空軍とともに資格認定活動で有意義な進展を続けている」とVanNierop氏は述べています。

Defense Newsは2021年12月、ボーイングが買収の技術・製造開発段階から生産に移行する正式な決定(「マイルストーンC」決定と呼ばれる)を2023年7月に行う見込みと報じています。4月に発表されている空軍の2023年度予算要求によれば、このことが、2023年10月から12月の間に起こると試算されています。

Boeing also anticipated the program would reach “initial operational capability,” or the minimum number of aircraft and other resources needed to perform a basic set of missions, in 2024. The Air Force budget pegs that to early fiscal 2026.

Boeing recently said it would pay the Air Force $285 million for charges related to the plane’s late-stage development and production. The Air Force directed a request for details on the fines to Boeing; the company declined to answer.

“Boeing and the USAF are working to shift as much test discovery and resolution as early as possible in the test program in [calendar year] 2023,” Stormer said. “The program is continually investigating strategies to improve the schedule to deliver the T-7 to [Air Education and Training Command].”

AETC commander Lt. Gen. Brian Robinson said during a live taping of the War on the Rocks podcast in Orlando, Florida, on Nov. 30 that the T-7 remains a “very capable” and “flyable” aircraft.

Still, his organization is considering how further delays to the program may affect the Air Force’s ability to graduate new fighter and bomber pilots using the legacy T-38, which was first delivered in 1961 and upgraded to the current T-38C starting in 2001.

“The T-38 was designed against the F-100 series type of aircraft,” Robinson said. “The skills can translate [to modern aircraft]. They just don’t translate as cleanly or as quickly as they otherwise would.”

また、ボーイング社は、このプログラムが2024年に「初期運用能力」、つまり基本的な一連の任務を遂行するために必要な最小限の航空機とその他の資源に到達することを予想していました。空軍の予算では、2026年度初頭に達するとされています。

ボーイング社は最近、同機の後期開発・生産に関連する費用(ペナルティー)として2億8500万ドルを空軍に支払うと発表しています。空軍はボーイング社に罰金の詳細を尋ねましたが、同社は回答を拒否しています。

“ボーイングとUSAFは、2023年のテストプログラムのできるだけ早い段階で、できるだけ多くのTest discovery and resolution (テストの発見と解決)をシフトするように取り組んでいますとストーマーは述べています。”プログラムは、航空教育訓練司令部にT-7を提供するためのスケジュールを改善するための戦略を継続的に調査しています“と付け加えています。

AETC司令官ブライアン・ロビンソン中将は、11月30日にフロリダ州オーランドで行われたWar on the Rocksポッドキャストのライブ収録で、T-7は依然として「非常に有能」で「飛行可能」な機体であると述べています。

しかしながら、彼の組織は、プログラムのさらなる遅延が、1961年に最初に納入され、2001年から現在のT-38CにアップグレードされたレガシーT-38を使用して新しい戦闘機や爆撃機のパイロットを卒業させる空軍の能力にどのように影響するかを検討しています。

「T-38はF-100シリーズに対抗して設計されたものだ」とロビンソンは主張しています。「T-38はF-100シリーズを想定して設計されたもので、その技術は現代の航空機にも応用できます。 “ただ、これほどきれいに、あるいは素早く変換することはできない”とも述べています。

「T-38はF-100シリーズに対抗して設計されたものだ」とロビンソンは主張し、「T-38はF-100シリーズを想定して設計されたもので、その技術は現代の航空機にも応用できます。ただ、これほどきれいに、あるいは素早く変換することはできない“と述べています。

空軍は今年1,500人近いパイロットを養成することができるのか?

Can the Air Force train nearly 1,500 pilots this year?

ORLANDO — The Air Force aims to train around 1,470 new pilots in fiscal 2023, which remains a lofty goal amid an enduring shortage of flyers.

Though the target is close to the service’s plan to graduate 1,500 pilots per year by 2024, hitting it will be a challenge, said Air Education and Training Command boss Lt. Gen. Brian Robinson during a live taping of the “War on the Rocks” podcast here Wednesday.

“We are doing the best we can with the resourcing levels that we have, in terms of manning, weapons system sustainment, parts and supply, things of that nature,” he said.

The service has spent the past several years modernizing that curriculum, hoping to speed up pilot production while helping airmen retain more information.

Robinson said he’s concerned about meeting the twin needs of improving flight school while also preparing for a possible conflict with a country like China or Russia. If a crisis requires the Air Force’s pilot training bases to start six- or seven-day workweeks, he said, then so be it. But that’s unlikely unless the U.S. goes to war with another world power and urgently needs more pilots.

Still, some instructors say they are struggling with a crushing workload. Flight simulator instructors are also hard to come by, with many heading to commercial airlines or other private companies even as the Air Force increasingly turns to virtual training.

空軍は2023年度に約1,470人の新米パイロットを養成することを目標としているが、飛行士不足が続く中、これは依然として高い目標です。

この目標は、2024年までに年間1,500人のパイロットを卒業させるという空軍の計画に近いものですが、それを達成するのは難しいだろうと、航空教育訓練司令部のボス、ブライアン・ロビンソン中将が水曜日にここで行われた「War on the Rocks」ポッドキャストのライブ収録でのべています。

「我々は、人員配置、兵器システムの維持、部品や供給、こうした全ての要求事項の観点から、我々が持っているリソースのレベルでできる限りのことをしている “と彼は述べています。

空軍は過去数年間、カリキュラムを近代化し、パイロットの生産を早める一方、飛行士がより多くの情報を保持できるようにしたいと考えてきました。

ロビンソン氏は、中国やロシアのような国との紛争に備える一方で、飛行学校の改善という2つのニーズを満たすことを懸念していいます。もし、危機が迫って空軍のパイロット訓練基地が週6日か7日の勤務を始めなければならないのなら、それはそれで仕方がないと彼は述べています。しかし、米国が他の国と戦争になり、パイロットが緊急に必要にならない限り、その可能性は低いと思われます。

それでも、教官の中には、過酷な仕事量に悩んでいるという人もいる。フライト・シミュレーターの教官もなかなか見つかっていません。空軍がバーチャル・トレーニングにますます力を入れるようになっても、多くの教官は民間航空会社や他の民間企業に移ってしまうからです。

A widespread ejection seat issue that required the Air Force to check hundreds of training aircraft to see whether the seats would work as intended also waylaid the enterprise this year.

Robinson suggested it’s time to rethink the training pipeline altogether.

“Probably, I need to get away from calling it the ‘pipeline,’” he said.

“Here’s the training criteria, the competencies you need to demonstrate, and once you’ve demonstrated them, you’re on to the next piece,” Robinson said. “But … you can’t move them through without regard for the other portion of the system.”

That can cause another problem, though: an unpredictable, fluctuating volume of student pilots at various points in the program. Robinson also worries airmen won’t feel as connected to their pilot training cohort if courses are more individualized.

“Culturally, that’s a challenge. We’ve experienced some of this as we looked at Pilot Training Next,” he said, referring to the flight school program that uses iPads and other technology to streamline those lessons.

“When we think about esprit de corps and unit camaraderie and unit identification, it’s disruptive to that model,” he added.

射出座席の問題が広範囲に発生し、空軍は何百機もの訓練機をチェックし、射出座席が意図したとおりに作動するかどうかを確認しなければならなくなり、今年もこの事業は失敗しました。

ロビンソン氏は、訓練パイプラインを全面的に見直す時期が来ていることを示唆し、“おそらく、それを パイプライン”と呼ぶのはやめるべきでしょう”と述べています

「トレーニングの基準、つまり、あなたが実証する必要のあるコンピテンシーがここにあり、あなたがそれを実証したら、次の段階に進むのです」とロビンソンは主張し、“しかし……システムの他の部分を無視して、彼らを移動させることはできないのです”と付け加えています。

しかし、それは別の問題を引き起こす可能性があります。それは、プログラムのさまざまな段階で、学生パイロットの数が予測できず、変動することです。また、ロビンソン氏は、コースがより個別化されると、飛行士がパイロット訓練の仲間とのつながりを感じられなくなるのではと懸念しています。

「文化的な問題です。パイロット・トレーニング・ネクストでは、iPadやその他のテクノロジーを使って授業を効率化する飛行学校のプログラムについて、「私たちはこのようなことを経験しました」と語っています。

「エスプリや部隊の仲間意識、部隊の識別を考えるとき、このモデルは破壊的です」と彼は付け加えています。

それでもロビンソン氏は、空軍が従来の学部でのパイロット養成モデルを打破する可能性を示唆しています。今までは、訓練生は、年間を通じて順次始まるいくつかのクラスのうちの1つに入り、数週間一緒に過ごした後、その同じクラスと一緒に卒業するのです。

新しいアプローチでは、訓練生を同じ時期にスタートさせ、次のステップに進む準備ができた時点で、新しい卒業クラスに分けることができます。

そうすれば、学習速度が遅い受講生がより複雑な機体に進む前に、より多くの時間をかけて教材を学ぶことができ、早くレッスンを受けられる受講生を抑制することもないからです。

重要なことは、特定の訓練スケジュールに従ったかどうかではなく、十分に準備された飛行士をタイムリーに運用部隊に送り込むことです、とロビンソンは付け加えています。

パイロットの年間生産目標は、経験豊富な飛行士を確保するための長期的な解決策と同様に、しばしば捉えどころのないものになりがちです。実際には、パイロットは訓練や休養の代わりに、より多くの任務とより長い出撃のために割り当てられることになるからです。

現役の空軍には12,000人以上のパイロットが所属しています。空軍は通常、航空国家警備隊や空軍予備隊のパイロットを含め、21,000人という包括的な目標に約2,000人不足しています。

「私たちは、飛行士とその家族の生活の質、そして国家にその能力を提供するためのサービスの質のバランスをとるスイートスポットを見つける努力をするでしょう」とロビンソン氏は言ってます。

Still, Robinson suggested the Air Force could break its traditional undergraduate pilot training model. Students join one of several classes that start throughout the year on a rolling basis, and graduate alongside that same cohort at the end of several weeks together.

A new approach could start trainees at the same time, but group them into new graduating classes based on when they’re ready to move on.

That could give slow learners more time to learn the material before advancing to more complex aircraft, without holding back those who pick up the lessons sooner.

What matters is that operational units receive well-prepared airmen in a timely manner, not just whether an airman followed a particular training schedule, Robinson added.

The service’s annual pilot production goals often prove elusive, as does a long-term solution for retaining experienced aviators. In practice, that shortfall means pilots are assigned to fly more missions and longer sorties instead of training or resting.

More than 12,000 pilots serve in the active duty Air Force. The service typically falls about 2,000 pilots short of its overarching goal of 21,000, including those who fly for the Air National Guard and Air Force Reserve.

“We’ll find that sweet spot that balances the quality of life for our airmen and their families and the quality of service for delivering the capability for the nation,” Robinson said.

About Rachel S. Cohen

The T-7 takes shape: Inside the factory where the Air Force’s next trainer is being built

Dec 17, 2021

ST. LOUIS, Missouri — In a factory in St. Louis that once helped launch the U.S. space program, the Air Force’s next generation of training aircraft is taking shape.

Boeing’s T-7A Red Hawk is still years away from reaching initial operating capability. But during a Wednesday visit to the factory where the new plane is being assembled, Boeing officials were bullish on its future potential — not just as a trainer to teach new pilots, but also as a model for how to build future aircraft.

The high-tech methods Boeing used to design and build the T-7 are saving time, simplifying processes, improving quality and cutting down on defects, company officials told reporters.

“Everything’s in 3D, everything’s digital,” Boeing vice president and T-7 program manager Paul Niewald said. “It’s an authoritative source of data. So our technical publications, our flight manuals, our service manuals, they all use the same data that the engineers are using, that our mechanics are using to build the airplane.”

In 1960, when the St. Louis facility was run by Boeing predecessor McDonnell Aircraft, engineers in white coveralls and caps assembled Mercury capsules in a clean room here. And more than half a century ago, this factory cranked out scores of F-4 Phantoms for the military to wage war in Vietnam, hitting its single-month production peak at 72 in June 1967.

But now, Boeing sees a highly digital future for aircraft design and production unfolding here, with the T-7 paving the way. And manufacturing lessons learned from the T-7 have already helped in the creation of the Air Force’s new F-15EXs and the secretive Next Generation Air Dominance fighter, said Matt Giese, Boeing’s chief test pilot for the F-15EX.

The Air Force in 2018 awarded Boeing a $9.2 billion contract to build 351 of the trainers to replace the aging T-38 Talon.

Boeing used model-based engineering tools and advanced manufacturing techniques to go from the concept of what would become the T-7 to its first flight in three years, Niewald said.

Advancements in high speed computing allowed Boeing to carry out computational fluid dynamics analyses and get aerodynamic characteristics to the plane’s designers earlier than usual, he said. This shaved seven to nine months off the typical process, in which wind tunnel models would have been used to gather that information.

It wasn’t the first time model-based engineering and 3D tools were used to design a plane, but Boeing used them to a greater extent than ever before. The digital design process meant Boeing could know exactly how the parts would align and fit together and precisely where all the holes needed to go. That meant the supplier could pre-drill all the holes so they’d be fastener-ready upon delivery to Boeing’s factory — meaning no need for drilling on the T-7 line.

Boeing said this approach allows it to both improve the quality of its build and cut down on mistakes such as incidents of foreign object debris — a problem that plagued the company’s production of the KC-46 in 2019 and led to a temporary delivery halt and grounding of the Pegasus on Boeing’s production line.

If there’s no drilling on the line, Niewald said, there’s less risk of metal shavings or other debris that need to be swept up afterwards and could cause problems if missed. Concerns about FOD are omnipresent, with signs urging mechanics to watch out for debris posted throughout the facility.

“By having a fastener-ready design, we’ve eliminated a lot of the touch labor and the defects that go along with that,” Niewald said. “Drilling on assembly is the No. 1 defect that you usually find in a traditional line.”

Pre-drilling parts before they reach Boeing’s facility also yields another benefit: A significantly quieter workplace. When Boeing built its first two T-X airplanes for the competition, Niewald said, the hangar was so quiet the mechanics could even, for the first time, ask for music to be played over the loudspeaker.

The factory was also relatively quiet the day of the reporters’ visit, aside from conversations and the hum of machinery as mechanics worked on T-7s, MQ-25s and other aircraft. Towards the end of the visit, someone piped in AC/DC’s “Back in Black,” echoing throughout the cavernous factory.

Identical airplanes, no shims

The precision of the model-based design also allows the T-7′s forward fuselage sections, built in St. Louis, to be quickly and easily combined with the aft sections built by Saab in Sweden, Niewald said — far faster than a traditional build would.

Saab is moving its production of the T-7 aft fuselage to a newly-opened facility in West Lafayette, Indiana, to make the shipments to St. Louis easier. Saab’s Swedish facility has three more fuselages to build, after which it will ship its remaining equipment to Indiana.

The precise fabrication of parts also means the T-7 can be put together without needing shims, the thin pieces of materials inserted to fill gaps between panels, Niewald said.

“The first two airplanes we built [are] the most identical airplanes we’ve ever built at the site,” Niewald said. “And that’s going to continue with the shimless design; everything will be the same.”

This doesn’t just pay off in the build process, he said, but also in sustainment. As the T-7 needs maintenance or modification in years to come, he said, maintainers will find all parts for the plane are exactly the same, making it easier to pop a new one in without adjustment. Niewald said Boeing brought the mechanics who would build the T-7 and the maintainers who would sustain it into the clean-sheet design process early on.

That paid off in a simple, but effective, ergonomic change in how mechanics and maintainers access the T-7′s avionics, Niewald said. Older planes often had the door panels covering avionics swing up, which forced maintainers to stoop down to make repairs or modifications.

But maintainers asked the T-7 designers if the avionics doors could instead swing down, allowing easier access and giving their backs a break.

Boeing’s mechanics also use touch-screen tablets to guide them as they build the T-7, so they have work instructions and specifications at the tap of a finger. That way they can quickly look up, for example, what size clamp is needed on a certain hose instead of walking over to consult paper blueprints on a table.

The simulators used to teach pilots how to fly the T-7 were built using the same engineering data as the aircraft itself, as well as running the same operational flight program software. This means in the future, when the aircraft gets a software update, the simulator’s software will be updated in a single push, Niewald said. Other aircraft’s training devices usually get upgraded software a year or two after the plane, creating a gulf in what pilots are learning on versus what they actually fly.

Supply chain woes

As with the rest of the defense industry, supply chain problems spawned by the pandemic have complicated and delayed T-7 production, Niewald said. It was particularly challenging because the program relies on a brand new supply chain that was just starting up as the pandemic erupted.

Niewald said the program lost about seven months due to a variety of supply chain issues, including shortages of microchips needed for the T-7′s avionics. Travel shutdowns worldwide also led to problems, he said, as experts weren’t able to travel to other countries overseas to help with engineering, inspections or processing for needed parts. What’s more, some workforces had to take on additional jobs to cover for people out on quarantine, further complicating supply chain issues, he said.

“We’re still seeing some residual impacts from the pandemic,” Neiwald said. “But this is an amazing team, and it will continue to claw back and try to accelerate as much as they can, from a mitigation standpoint.”

The damage has already been done to the T-7′s schedule. COVID-related parts shortages were among the factors this summer that led the Air Force to announce it has pushed back the T-7′s milestone C, or a decision clearing the plane to enter full production, by more than a year. The Air Force said at the time that milestone might be reached in late 2023.

Niewald said Boeing believes the T-7 will hit milestone C in July 2023, slightly sooner than the Air Force’s prediction earlier this year. He also said an initial operating capability declaration is likely to come sometime in 2024.

“We are working as best we can to move things to the left,” he added.

And Boeing is confident the T-7 will be able to evolve to meet Air Combat Command’s desire for an Advanced Tactical Trainer, which it wants to better train new fighter pilots how to fly in combat.

“We designed this thing with growth in mind,” Niewald said. “The whole digital concept [of the T-7] is that it’s easily upgradable [so] that we can go forward, whatever requirements, or whatever future training needs are represented. The digital foundation of the T-7 will allow [Air Education and Training Command] to build upon that for decades to come.”

About Stephen Losey

Stephen Losey is the air warfare reporter for Defense News. He previously covered leadership and personnel issues at Air Force Times, and the Pentagon, special operations and air warfare at Military.com. He has traveled to the Middle East to cover U.S. Air Force operations.

T-7 Red Hawk trainer makes its debut

Friday, Apr 29

WASHINGTON — The first of the U.S. Air Force’s new fleet of trainer jets, Boeing’s T-7A Red Hawk, was unveiled to the public in a rollout ceremony Thursday in St. Louis, Missouri.

The event, held in a Boeing facility at Lambert International Airport, marked the first delivery of 351 planned T-7s, which will replace the more than 5-decade-old T-38 Talon aircraft.

Boeing received a $9.2 billion contract in 2018 to create and deliver the Air Force’s new trainer, which was designed to teach pilots to fly fourth- and fifth-generation aircraft.

The T-7 was named in honor of the famed Tuskegee Airmen of World War II, the first squadron of Black fighter pilots who broke racial boundaries and were nicknamed the “Red Tails” after their planes’ distinctive markings. The T-7′s own red tails are another nod to that legacy.

Retired Lt. Col. George Hardy and children of the late Brig. Gen. Charles McGee, both of whom were Tuskegee Airmen, attended the event. The debuted T-7 bore Hardy and McGee’s names below the cockpit canopy.

“With this rollout, we honor our storied history and the heroes who wrote the chapters, and we usher in an exciting new era of aviation and a new generation of heroes who will write the next chapters,” Air Force Academy Superintendent Lt. Gen. Richard Clark said.

Boeing used high-tech digital engineering tools to design and build the T-7, allowing it to move from a concept to its first flight in three years — faster than the typical timeline for aircraft development.

Air Education and Training Command head Lt. Gen. Brad Webb said the T-7, which was designed to emulate a fifth-generation fighter, will be crucial as the service revamps its pilot training programs. Within a decade, Webb said, nearly 60% of the Air Force’s combat pilots will be flying fifth-generation fighters.

The first T-7 will next undergo a series of ground checks and taxi tests before it makes its first flight in the next few weeks, the Air Force said. It will fly to Edwards Air Force Base in California later this year for further flight tests.

The 99th Flying Training Squadron, which was originally formed to train the Tuskegee Airmen and still trains pilots today at Joint Base San Antonio-Randolph in Texas, will be the first squadron to receive the T-7, Webb said.

Webb also noted that Tuskegee Airmen celebrated successful missions during World War II with a bottle of Coca-Cola, and that the 99th currently celebrates trainees’ graduations by popping open the soda.

About Stephen Losey

Stephen Losey is the air warfare reporter for Defense News. He previously covered leadership and personnel issues at Air Force Times, and the Pentagon, special operations and air warfare at Military.com. He has traveled to the Middle East to cover U.S. Air Force operations.

Best regards,

Shoichi Sugiyama, Ph.D.